- Home

- About Us

-

Product

- Air headers

- Ball Valves / SS Ball Valve/High Pressure Ball Valve

- Check valve /SS CHECK VALVE

- Compression Tube Fitting

- Condensate pot

- Hydraulic Fitting

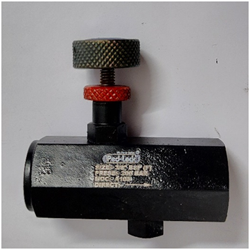

- Hydraulic flow controls valves (D.R.V)

- Hydraulic Valve

- Instrument Accessories

- Instrument Valve

- Manifolds valves

- Precision Pipe Fitting

- Safety valves

- Needle Valves / SS Needle Valve

- Exhibition

- Certificate

- Inquiry

- Contact Us